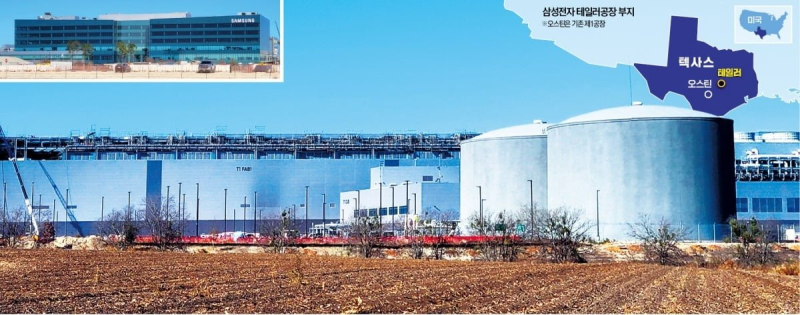

⬤ Samsung Electronics is pushing hard to get its Taylor, Texas foundry across the finish line. The company's planning to fire up extreme ultraviolet lithography equipment for testing in March, with etching and deposition tools coming online right after. Full-scale production is targeted for the second half of the year. This isn't just another facility—it's Samsung's first foundry built outside its home turf, and it's become central to the company's push to stay competitive in cutting-edge chip manufacturing.

⬤ The pace at the Taylor site has ramped up dramatically. More than 7,000 workers are on-site every day keeping construction moving, while over 1,000 employees have already settled into the office building. Samsung's getting ready to file for a Temporary Certificate of Occupancy, which would let them start using parts of the facility once safety checks clear. To make sure production yields come up to speed quickly, the company's brought in a wave of senior engineers from headquarters.

⬤ The facility already has its first major customer locked in. Samsung will be producing next-generation autonomous driving chips—the AI5 and AI6 models—for Tesla under a contract worth roughly $16.5 billion that was signed last July. If Samsung can nail the performance and yield targets for Tesla, other major tech companies could follow with their own orders. The Taylor site sits on enough land to eventually support up to 10 fabrication plants, setting it up as a long-term expansion hub for the company.

⬤ Everything rides on Samsung's ability to deliver consistent yields with its 2nm Gate-All-Around process. Pull that off, and Samsung could strengthen its position in the global foundry race while giving major tech players another option for sourcing advanced AI and high-performance chips as demand keeps climbing.

Peter Smith

Peter Smith

Peter Smith

Peter Smith