These new and unique laser modules developed for outstanding applications are advanced solutions to achieve high-end results with cutting metal/wood, so these certainly have a role in the current or anyone's workshop, as well as any industrial applications.

The latest series of Xlaserlab modules has been developed from the very best technology in hardy and efficient diode lasers to provide an affordable, simplified option for a seasoned or new do-it-yourselfer or small business. With them, the toughest laser wood cutting machine jobs and amazing laser metal cutting could not go away, everything behind, if it regards a very simple change between excellent designs and large-scale projects. For creators who aim to expand their income potential, exploring ways to make money with a laser engraver has become a practical opportunity powered by Xlaserlab’s innovation.

Performance and robustness are the key features in these laser modules, according to the company. Light and compact, simple installation without trimming in the workplace, such as a home studio and a professional production place, can be mounted. With cutting-edge optics technology, efficient high-power handheld laser output, and easy control features, this is the best solution for any on-site welder or installer to ensure precision performance while limiting errors, so that you can save more.

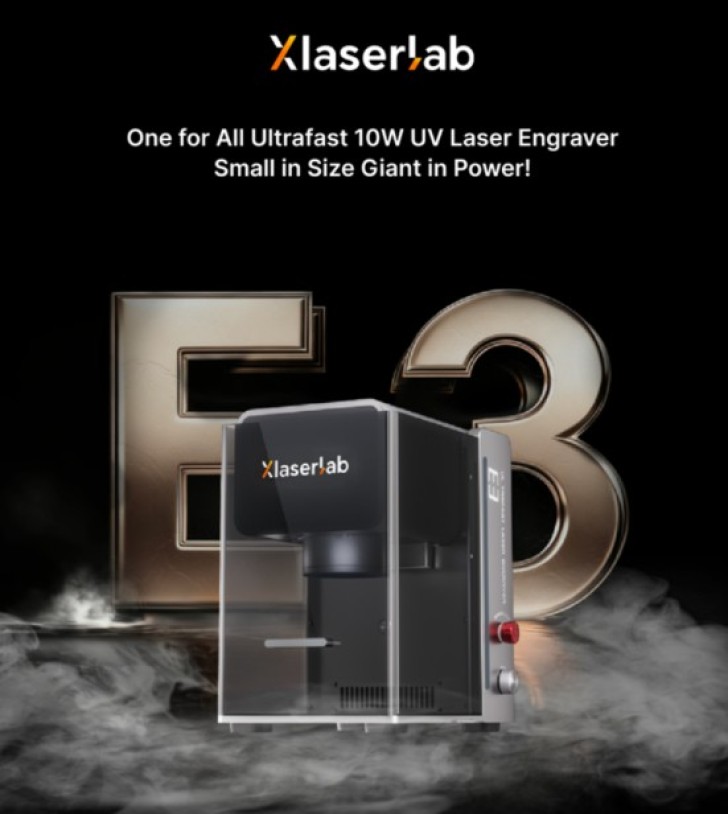

Xlaserlab has also recently initiated a crowdfunding project for its new solution, the E3 UV Engraver, on Kickstarter. This initiative is yet another example of the company’s commitment to innovation and driving high-performance, reliable laser technology into the hands of numerous people through the assistance of the community.

Xlaserlab spokesperson explained: Our customers have the freedom to select any of our new laser modules that correspond with their specific application needs. Whether it’s projects for a precision laser wood cutting machine, or the rigs of a massive laser metal cutting machine, we wanted to make sure the device can handle all what you throw at it. We’re here to empower the creators and businesses doing real AI that matters, to bring them the software tools they need that will make them efficient.

It is always Xlaselab ‘s solution to break this smaller max limit of a small laser. These high-tech materials can be very useful for home or business use. From which the full range of operation, ranging from intricate wooden patterns, plastic supplies, personalized signs and engravings, to metal parts, was now feasible. They are also great for testing and low production runs by freeing up the need for technicians to run several machines.

And this set of new modules is here to last. Xlaserlab engineers added more heat-lowering circuitry, braced up even more interior components, and, as a section notes, mounted the lens mounts to survive. So they are excellent in any situation where you just want to externally control a relay without guessing how everything will work.

The simplest action, but also extremely consistent performance, safety, and user experience, is the cornerstone of Xlaserlab. Smart Protection Structures- every module designed within the protections of Over-voltage, under-voltage, over-trip, and short-circuit; Visual operation LED Indicator: reduces users’ insecurity. These safeguards are in addition to the mod’s pro-grade capabilities, so whether you’re a newbie or an old hand vaper, you can feel confident that you’ll vape safely.

Xlaserlab has also prioritized accessibility. To inform users on how to use a project work appropriate laser wood cutting machine rightly, they educate users with their in-depth user and how-to guides that are available on the company insights blog, such as pen type collection, safety products, and CO2 metal cutting have complete product specifications for industrialists. Because when you combine this can-do advice along with the powerful tools inside, you’re going to be able to turn your work into art—all while getting all the support and encouragement we're famous for. Through their Xlaserlab Academy, users can also explore detailed lessons on laser engraving materials to refine their skills and ensure the best results.

Additionally, there is a rather wide range of material support, another reason to choose these laser modules from Xlaserlab. They work right on Hardwoods - Maple, Cherry, and Soft materials like Aluminum, Stainless, or Titanium. Designers, creators, and engineers can iterate through the design process and prototype a product that has been designed to not lose accuracy across materials and part types.

The new laser module generation. Her members connect with further world-class robustness, flexibility, and reliability. As a result, we have found that with the capability to jump from, say, laser wood cutting machines to laser metal cutting machines, these units have become downright versatile modules and can really work them in other projects. These models are intended to be used by beginners and professionals as we apply both detailed forms of product to production-grade detailing.

About Xlaserlab

Xlaserlab provides enterprise and consumer laser solutions for engraving, welding, cutting, and cleaning. To meet the needs of different customers, the company provides X1 PRO, E3 UV Engrav, etc, and new generation laser modules, etc, and the new high-power solid-state laser makes a breakthrough in processing design. Quality is Key Xlaserlab focuses on customer and production-ready quality performance that enables content creators, engineers, and businesses around the world.

To find out more about Xlaserlab’s new generation laser modules, or to discover products like the laser wood cutting machine and the laser metal cutting machine, check out their website at www. xlaserlab.com.

Editorial staff

Editorial staff

Editorial staff

Editorial staff